- This topic has 11 replies, 7 voices, and was last updated 10 years, 5 months ago by .

-

Topic

-

vehicle: 1995 ford ranger 2wd

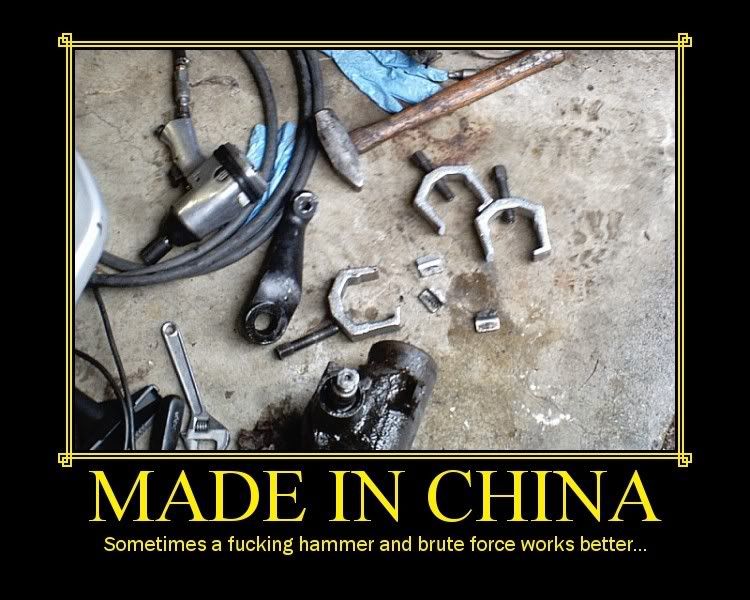

I just spent a good 8hrs trying to get this damn pitman arm off. I broke 2 pitman arm pullers and it is still stuck. I’ve tried heat, impact gun, and a BFH. Any suggestions on getting this thing off. Btw its in the truck, not on a bench.

- You must be logged in to reply to this topic.

Our Address

Our Address