- This topic has 11 replies, 6 voices, and was last updated 9 years, 12 months ago by .

- Topic

I’ll start by saying that I’m writing this by request, posting publicly hoping to help out whoever I can as usual. I’m also likely to edit this multiple times, it’s tough to sum up all at once. Anyone who can add more of these kind of tips is encouraged to post, I’m certainly not the authority on this subject.

I am not a particularly fast tech, but I’m a substantially reformed slow tech. I learned my trade doing hobbyist work on my VW for 6 years at home. Even a brake job would be dragged out to at least a day of cleaning, polishing, lubing, painting, etc to make everything perfect. Getting into professional repair, I had to spend years learning what I corners I could cut to finish the work fast enough, and then how to speed up what I still do. To this day, I cannot bring myself to install a fastener that squeaks or doesn’t thread in easily. My personal wire wheel bench grinder is one of my best tools for keeping fast while being anal like that.

Wasted motion is a big time sucker, as is disorganization. Refining these areas is of great importance to speeding up.

When I’m taking a transmission out for example, I have a few ways I save time by not wasting motion. First is removing fasteners in such a way that minimizes tool changes, going around the whole job and removing all the bolts that the tool in my hand fits. The point is to avoid focusing on taking one thing apart at a time, picking up and putting down the same 5 tools for each part you take off. Second is taking apart/loosening everything on top so when I lift the car I will not have to lower it back down until the transmission is back in and everything on the bottom is fully installed. Raising and lowering to go back and forth between top and bottom wastes major time.

A time saving technique on any large jobs is removing assemblies as large as possible when you’re just taking parts out of the way to get to the repair. Perfect example is a engine job where you need the radiator/condenser/intercooler/oil cooler all to come out. Removing the whole cooling cassette (BMW terminology) as an assembly as opposed to taking out each part individually saves a lot of time. Thermostat housings/coolant manifolds made up of multiple aluminum pieces and tons of hoses are another common example.

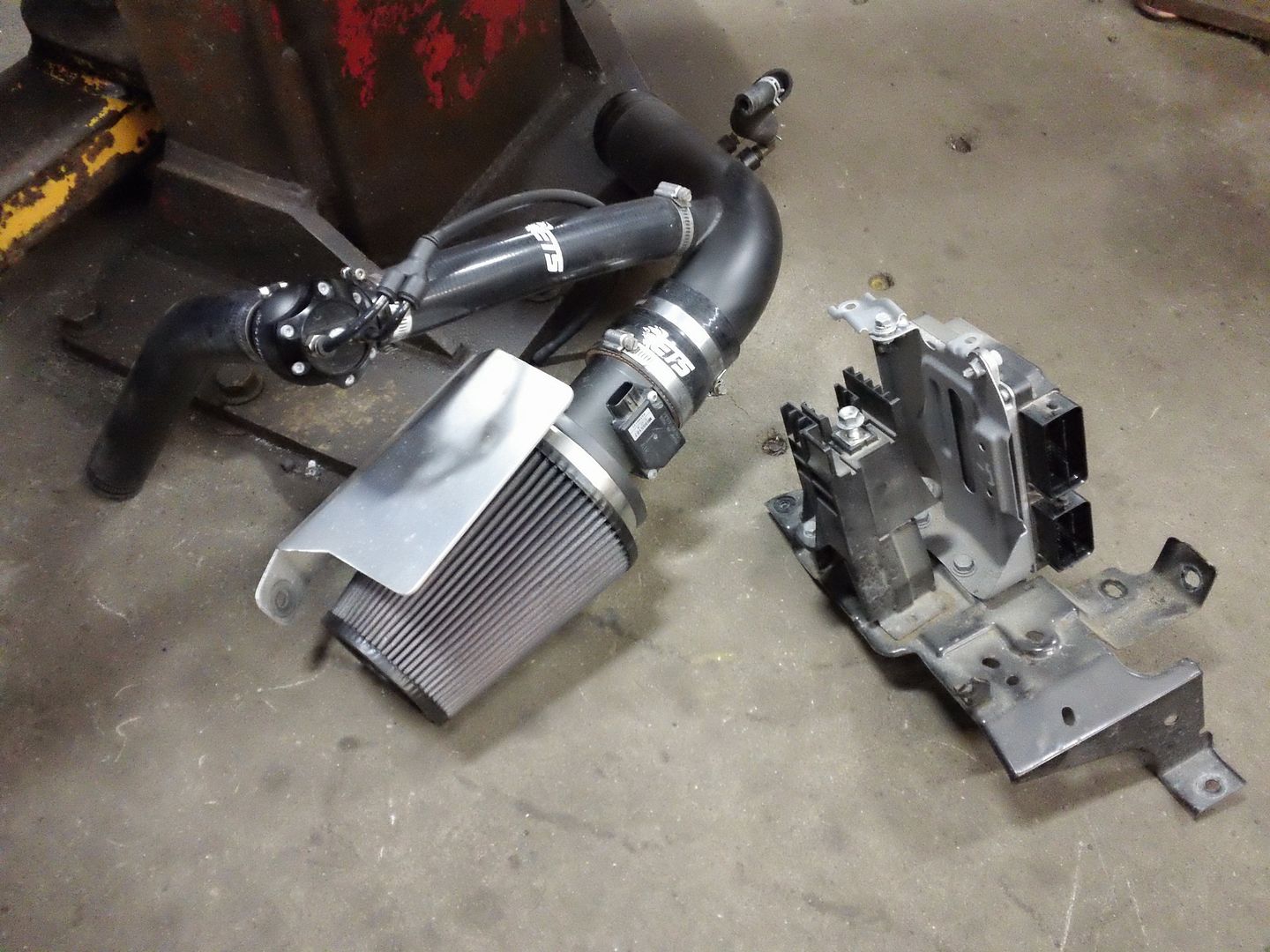

On that Evo engine job I posted up about recently, I needed the power steering pump, lines, and reservoir out of the way to remove the head. Quickest route there is to unbolt that stuff, leave it all attached to each other, and flop it all up out of the way. I’ve seen other guys take the lines of the pump and then take the pump off and set it aside. They spend more time taking it apart, have a oil mess that doesn’t need to be there, and then have to get fluid from parts and bleed air from the system when they’re done. Lots of wasted time saved.

Another way to save wasted motion is to have a service cart/tray available to work off of. Just a simple $50 flat surface with no drawers that can be easily rolled around and most importantly, is clean and ready when you start a job (not used for storage). Then you can pile the tools you figure you’ll need on, and roll it over next to where you’re working and try to stay there. Walking back and forth to your toolbox is wasted motion.

Having a wide array of parts trays to keep your removed fasteners and sockets in their places. On big jobs this helps fight the tendency to be wasting time looking for small tools you have out and have picked up an put down endless times. Keep it all laid out on that cheap, simple service tray. Spend the 1 or 2 min/hour keeping it in order during a 9 hour job.

Have fluids draining and AC machines doing their thing while you are doing other work. Have your own personal drain pans designated for oil based fluid and water based fluid. A lot of shops will have them laying around to share, but keeping them clean and where they’re supposed to be is pissing up a rope. That brings me to a golden rule in this line of work:

A shared tool is an abused tool.

Screwing around with shop tool sets that are broken or missing pieces is one of the most aggravating wastes of time for me.

Another side of speeding up comes from spending money of expensive tools that save you time. That is a whole other side to this discussion although there are a couple specific tools I credit with productivity:

1) The aforementioned service tray that is clean and ready to work at moment’s notice

2) A Snap-On 3/8″ 14.4v or lithium cordless impact. The fastest guy I’ve ever seen uses one all day long, so I bought one. Guess who sped up.

3) The current generation Snap-On lithium 1/4″ cordless impact, 1/4″ impact swivel joint

4) A Power Probe

5) Duplicates of common wrenches and sockets. It saves massive time if you have a duplicate of that wrench you NEED RIGHT NOW but cannot find right now.

I also have to admit that the Mercedes payment tool storage I’ve upgraded to over the last couple years does directly speed up just about everything I do by a small percentage. I do still feel that tool storage should be multiple cheap units until you have all tools you need and then some. You also need to have a developed work style you’re well aware of in order to configure an effective workstation for yourself.

- You must be logged in to reply to this topic.

Our Address

Our Address