Home › Forums › Stay Dirty Lounge › Service and Repair Questions Answered Here › Honda Accord/CL **Rotor over Hub Conversion**

- This topic has 18 replies, 7 voices, and was last updated 13 years, 2 months ago by

philh.

philh.

- CreatorTopic

- November 23, 2011 at 11:00 am #446466

I’ve watched both videos Eric did on removing captive rotors on a Honda on a 97 Acura CL that I’m rebuilding.

Tried the long-bolt hammering method using an Ingersoll-Rand Model 117 Air Hammer (ridiculous power) on 4 Grade 8 Bolts.

- CreatorTopic

- AuthorReplies

- November 23, 2011 at 11:00 am #446467

I really couldn’t see doing this job with the knuckle still on the car. You should take it out and put the knuckle in vice, then have at it with the long bolts and a BFH (big effin hammer) – something at least 4 or 5 pound should work well. Sometimes these things need a few sharp, powerful blows, power that I think an air hammer won’t match. The hub should be fine.

I suppose it’s possible the bearing got damaged, but usually bearings are fine unless you are hitting directly on them – either way it looks like you need a new one. Since this job is pain, don’t go cheap on the bearings.

A method I used to separate the hub from bearing was I put pieces of scrap metal direct underneath opposite sides of the bearing. Then I tightened those same bolts into the scrap metal. So it’s basically the same principle as any other puller. I used a vice to install the hub into the new bearing. You could also bring the pieces to a shop and they would probably do it for you cheap. Good luck.

November 23, 2011 at 11:00 am #446468Thanks. Good info.

Along these lines, if I put long screws into the bearing from the back of the knuckle and continue to tighten, does it press against the rotor? If so, will that cause the bearing to be harder to remove from the knuckle since the force is being transferred to a much larger surface area?

Pretty frustrated — I’ve also seen people saying that since you’re replacing the rotors, just hit the rotors with a hammer from the back and it will pull the bearing out of the knuckle. Is this accurate? Or will it just separate the bearing?

Also, any guesses on if I damaged the bearing and caused the free play by air-hammering on the long bolts?

November 23, 2011 at 11:00 am #446469Philh,

I doubt you damaged a good bearing by beating on it. A bearing would only get damaged if the force of the hammer blow moved the rotor in and out against its designed movement axis. It can only do this if there is ‘play’ in and out on the wheel. If there was play in the wheel then the bearing was already bad. Bearings are made of steel pressed into a harder steel case (rotors). They are by default the ‘weak link’ in the axle; but are designed to take a tremendous amount of in and out force applied to the wheel. Force you can not generate with a hammer.

Do the math of a 1500 # car going into a turn traveling at highway speed. While rubber deformation absorbs some of that force, the force applied to the cross axis of the bearing is considerable. As long as the wheel has no play, the force is absorbed by the bearing case supported by the snug fit in the rotor. It would take a really big hammer to exceed that design limit by hand.

If it were not so, then bearings would wear out much faster than they do with all the force applied to them in the process of daily driving. If I am wrong, I would very much like someone to explain how.

November 23, 2011 at 11:00 am #446470I have almost 1/8″ of lateral movement at the edge of the rotor now.

I read a post where the person said the wheel bearing will become loose once the axle nut is removed — and that you can not test the play in the wheel bearing unless the axle nut is in place.Is this true?

If so, maybe I didn’t damage the bearing from hammering on the bolts.

**Update 11/24** Confirmed that the axle nut has nothing to do with bearing play.November 23, 2011 at 11:00 am #446471I’m no expert, but I think that is true. I tried to take off a hub to help get the rotor of of a Mazda 6, (I’m not too bright at times…) After I took the spindle nut off, and re-tightened it, I was soon replacing the bearing.

November 24, 2011 at 11:00 am #446472Okay, the first step is to put the knuckle into a vice. The second step is to thread your bolts into the bearing and pound the snot out of them.

After you separate the hub/bearing/rotor from the knuckle you completely take off the bolts that attach the rotor and remove that. If it’s hanging up, don’t be afraid to hit that with a hammer. A block of wood may be useful if you don’t want to tear up the surface of the rotor. Penetrating oil can help loosen rust.

The last step is to use the bolts pushing against the scrap metal inserted between the bearing and hub to separate it.

The bearing shouldn’t get loose once you loosen the axle nut because it is a sealed bearing. That is only true for tapered bearings or similar that need to be packed with grease.

November 24, 2011 at 11:00 am #446473I don’t have a vise, so was trying to pound away while still on the car.

Maybe I needed a Bigger BFH — Mine is 2 lbs.

But was surprised it just laughed at the Ingersoll-Rand 117.Any thoughts on the LT825 Wheel Bearing Hub Removal Tool?

Looks like it might be more effective than the bolts since it hits flush and directly on the bearing race.

http://www.sjdiscounttools.com/ltilt825.htmlNovember 25, 2011 at 11:00 am #446474Quoted From philh:

I don’t have a vise, so was trying to pound away while still on the car.

Maybe I needed a Bigger BFH — Mine is 2 lbs.

But was surprised it just laughed at the Ingersoll-Rand 117.Any thoughts on the LT825 Wheel Bearing Hub Removal Tool?

Looks like it might be more effective than the bolts since it hits flush and directly on the bearing race.

http://www.sjdiscounttools.com/ltilt825.htmlThat tool will work, you can use it in place of the ‘bolts’ as it goes into the back of the bearing itself so you can hit on the tool instead of the bolts while you drive the bearing out of the knuckle. I believe the ‘play’ you have is the result of you forcing the hub out of the bearing a little with the bolts as you suspect, when you run the bolts in you need to make sure you are running them into the indented area of the back of the rotor and not the raised area, I suspect that when you ran your bolts in that you started to force the rotor and hub out of the bearing and have separated it a little bit. You can go one of 2 ways at this point in my opinion, you could get the tool and use that to hammer out the bearing and rotors, put it all back together and run the axle nut down as good as you can to pull the hub back into the bearing. This MIGHT work without damaging the bearing but to be honest it could go either way in my opinion. The second option is just to get a slide hammer and slide hammer out the hub and rotor thus splitting the bearing. Once again after you replace the rotor you MIGHT be able to reassemble everything without damaging the bearing however I consider this unlikely and therefore I would recommend replacing the bearing as well as the rotor to ensure you don’t have to go back and replace the bearing because it was damaged in the process.

November 25, 2011 at 11:00 am #446475Eric – Thanks so much for the feedback — It’s been invaluable on this project.

At this point, I’ll take your advice and probably replace both bearings.

In fact, managed to snap off one of the 4 bolts holding the bearing in place on the opposite side — broke right where the threads begin — so both bearings.I’m tempted to go ahead and do the Rotor Over Hub conversion — All I need is two Hubs from a 98 Acura CL.

There is so much rust, not sure what condition the existing hubs are in. (Did I mention the car spent years in Ann Arbor Michigan?)

Any thoughts on doing the ROH conversion, since I’m close to replacing almost everything?

Assume that the bearing needs to be pressed onto the hub — but then I can use the bolts to pull the bearing into knuckle – Or should I just have a shop press both?Here are a few pics of my project:

Notice the incredibly poor the condition of the rotor — amazed it was barely in contact with the pads.

Drip pan in place, but no leakage when axle removed.

Broken bolt visibleNovember 25, 2011 at 11:00 am #446476Your project looks exactly like mine from last week. I just replaced the wheel bearings in my Accord and the knuckles look identical. That rotor is trashed. Not to much stoping power with that. If your at this point I would consider changing those bearings. 45$ per side for Timken bearings. How I got the hub punched out of the bearing, I used a 2″ black pipe connector and pounded it out with a ball pien hammer. Then I put the 4 bolts in like Eric shows in the video. I I had everything out in 5 to 10 minutes. I also have a friend that has a press, so I pressed in the new bearings. Check around with some people you know. Maybe someone you know has access to a press.

November 26, 2011 at 11:00 am #446477It probably wouldn’t hurt to do the conversion while you’re in there. The hubs are like 50 something from the dealer (cheaper online), or find something used and local. If you have trouble putting it together, don’t be afraid to find a machine shop or a garage to throw them together for you – it should take them 5 minutes and they shouldn’t charge you hardly anything.

November 27, 2011 at 11:00 am #446478The hubs needed for the Rotor Over Hub are from the 98 CL, Part # 44600-SY8-A00, and list for $132.47. Can get them for $96/each online.

Unfortunately, haven’t found any other source for this part.So, not inexpensive, but seems like replacing both bearings and rotors, might as well replace the rusted hubs too.

Is there any additional advantage/disadvantage – other than the obvious one of easier rotor swaps?

November 28, 2011 at 11:00 am #446479People ask me about that conversion often and to be honest I’ve never done it but I don’t think it would be difficult to do. As far as my thoughts on the matter however I don’t think it’s necessary as it’s not often you need to replace rotors and if they do need to be machined you can do so with an on-the-car lathe which is actually a better way of machining rotors anyway so in summery it’s really up to you if you want to go that rout.

December 4, 2011 at 11:00 am #446480Thanks for the replies. Here’s my latest update:

Finally got the bearing out of the knuckle.

Since I was replacing the rotors, bearings and hub (doing the Rotor over Hub conversion), hammered the old rotor and in the process pulled the bearing apart.

This was done with the knuckle out of the car.

Then, using an upgraded 40oz hammer (needed a bigger BFH), hit the heck out of the bolts screwed into the bearing and by the 3rd strike, could see the bearing moving out of the bore in the knuckle.Once removed, took a wire wheel to the knuckle bore but still looks like the bore is pretty rough.

Almost looks like some of the surface of the bearing has transferred to the bore.

Don’t know how bad this is or how important it is to try to remove every bit of it, but thought I’d post a couple pics.

Any feedback would be appreciated.

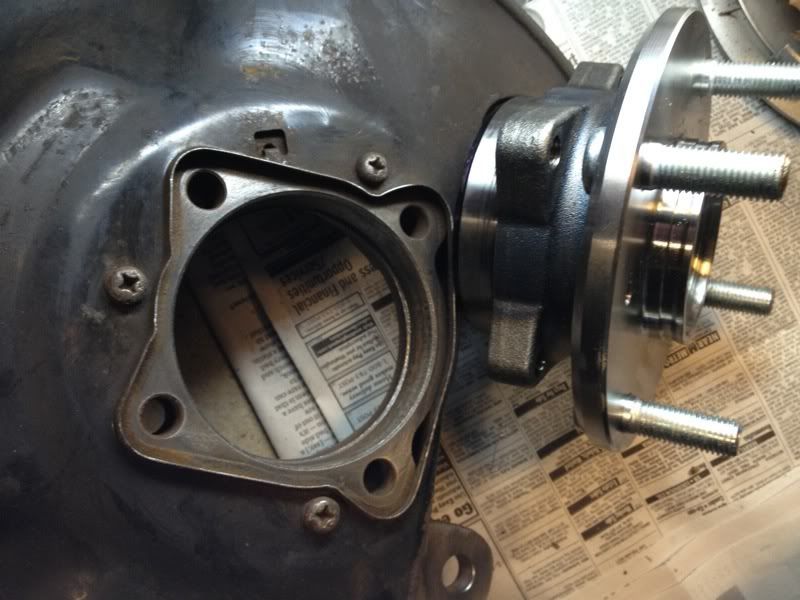

Just a little rust….December 11, 2011 at 11:00 am #446481Just completed the rotor over hub conversion.

Wasn’t too bad once I got the bearings out of the knuckle.

I took the new bearings and hubs (from a 98 Acura CL) to a machine shop and had them press it together.

They charged me $46 for both — took about 3 minutes.Everything went together easily — not difficult at all.

I put a little anti-seize on the bore in the knuckle where the bearing sits – Someone will thank me for this in about 10 years.

Here are a few pics:

Old rusted bearing – No wonder it was so hard to remove

Bearing pulled apart – Broken bolt remains visible

New bearing pressed onto 98 Acura CL Hub

Showing correct depth of hub in bearing

Bores cleaned up and ready to receive new bearing/hub

Bearing in Knuckle – Anti-seize visible

Knuckle re-installed on car (New axle also installed)

New rotors and calipers installed.

Almost too pretty to drive!Thanks for everyone for all the advice – really helped.

- AuthorReplies

- You must be logged in to reply to this topic.

Our Address

Our Address