[quote=”KnowNothing” post=136470]

Does anyone else do this? Or should I remove it quickly? Don’t even think it’s a good idea to use brake cleaner to remove this since it might just melt it and spread it, will have to rub it off with a shop towel or something first and then brake clean it using a rag or something rather than shooting it on.

I would have used anti-seize but that silvery stuff gets everywhere. No thanks. Did I mess up? Was this a stupid thing to do?[/quote]

Yes I do this but not with that product (and I would not use a “grease” product for that application either).

Basically alloy rims will fuse themselves to the hub and rotor hat surface over a couple of years and can be very difficult to remove. It is bad enough when tire places and workshops over tighten your wheel nuts making them almost impossible to remove but then finding that the wheel will not come off the hub is just as bad. I wonder how many people have had flat tires and found they could not budge the wheel. Loosening the wheel nuts by a small margin and running the vehicle back a forth to try and un-stick the wheel is probably what people have to resort to.

With one of my previous cars (still fairly new at the time ) I tried removing both front wheels to check my brakes for wear and I found it impossible to remove the wheels even by using a rubber mallet on them to try and tap them loose. I had to go to a tire place. After that, I well and truly solved that problem though.

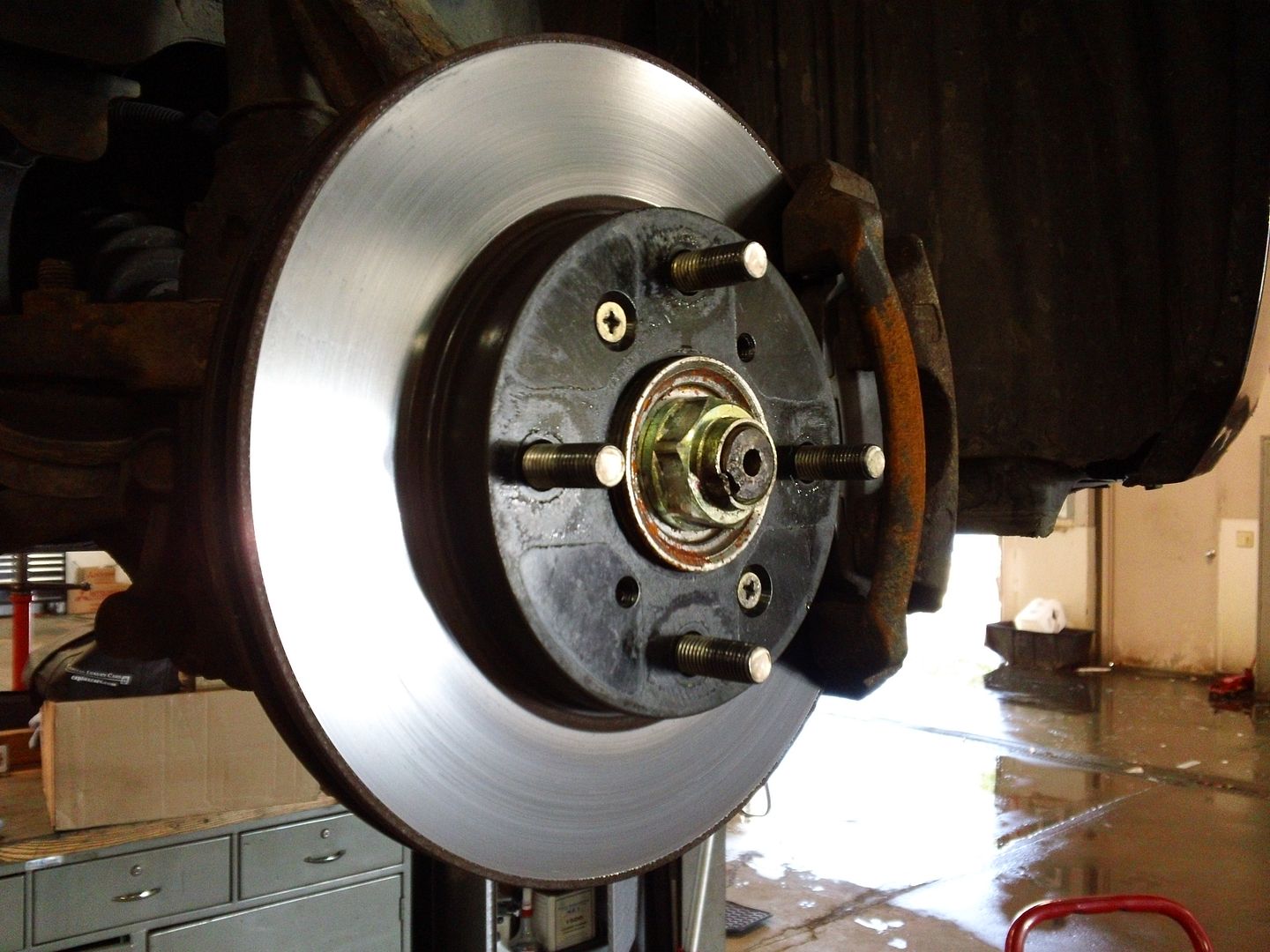

One of my current cars is 2.5 years old and spends most of its time garaged. When checking the front wheels recently(which had been removed by the dealership only a few days earlier), I found the wheels hard to remove even then because of rust around the hub area in particular. I cleaned up the hub and the rotor hats very well (especially where the alloy wheel center contacts it) with a small wire brush on a cordless drill, some hand wire brushing and some wet and dry sand paper. I also cleaned up the alloys so the centers were nice and clean especially where the center bore slides onto the vehicle hub. I then cleaned the surfaces with brake cleaner and finished off with cleaning the shiny rotor surfaces with brake cleaner and drying them off well.

My next step may not be recommended practice but it always works well on my cars with zero issues. I use a high end synthetic chain lubricating oil specifically made for lubricating chains and other parts of bicycles. This is a very thin oil. I smear tiny amounts of this lubricant around the inside and outside surfaces of the hub that are subject to rusting and also on the vertical rotor hat surfaces that contact the wheel center. I also smear a small amount onto the wheel center where it contacts the hub and rotor hat surfaces. I then use a couple of face tissues to pick up any obvious excess and to dab over the entire surfaces where the oil has been smeared to ensure that there would never be any lubricant leaching out or finding its way onto the rotor surface where the brake pads contact. I then clean the entire rotor again with brake cleaner on all areas not smeared with lubricant. This only takes a few minutes and the wheels slide on easily. More importantly, next time you have to remove the wheel you will find it has not glued itself to the hub and rotor hat surfaces.

I have also done this using the same lubricant on previous vehicles and have had absolutely zero issues after years of operation because I am careful with the amount of lubricant used and where it is placed so there can never be any prospect of the lubricant leaching out and running on to the shiny rotor surfaces. The process does work in stopping the alloy wheels fusing to the surfaces they contact when fitted up and the wheels do come away smoothly when the nuts are removed.

I do not know what the synthetic formulation of Silglyde is but given what it is designed for I cannot imagine you would have any issues at all using that product on the hub and rotor hat surfaces you treated provided you did not use too much but just a minimal smear of product. You do not want it migrating to other parts of the rotor. If you think you may have used a bit much then remove a couple of wheels and check and use a paper towel or face tissue to wipe away any excess product. It is heat resistant to over 400 F degrees so it is not going to dry up and it should continue to prevent rust build up on the surfaces it has covered given that it is designed to resist corrosion on metal surfaces.

http://agscompany.com/product/sil-glyde-silicone-brake-lubricant-tube-4-oz/

It may be worth pulling off a wheel in 3 or 4 months to see how well it is working.

Our Address

Our Address